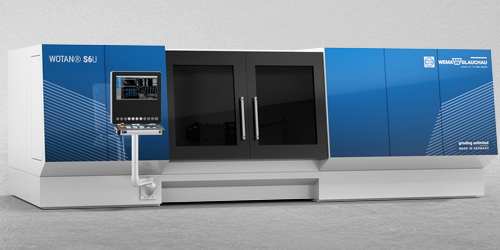

With WEMA SU a universal grinding machine is now available for the more complex task of the four-way machining of all major workpiece sizes. The machine is equipped with variably fitting external and internal grinding units. The resulting machining work with just one clamping operation provides decisive efficiency and precision benefits.

Versatility is the key to conferring a major edge. Our technology enables machines to perform highly complex operations. At the same time, our efficient peripheral modules allow a flexible reaction to your individual production requirements. This allows you to reduce labour costs and production times.

Key Facts

- 4 sides can be machined in one clamping operation

- Up to 3 swivel axes

- Machining of chuck and shaft-shaped parts (steady rest guided)

- Up to 4 insertable internal grinding tools (fixed on B2 axis) and 4 external grinding tools (fixed on B3 axis)

- External grinding wheels with a maximum of 600mm diameter

- various options possible (acoustics emission (AE), dressing spindles, CBN, etc.)

For #cylinders #cones #polygons #threads #eccentrics #grooves and much more

400/500 mm

650 / 820 mm

400/1,000 mm

1,450 / 2,950 / 3,200 mm

400 kg

650 / 1,300 kg

350 mm

650 mm

400/500 mm

650 / 820 mm

400/500 mm

1.200 mm

700 mm

2,000 mm

Options

- Revolver headstock with up to 4 internal grinding mandrels

- Fixed external grinding unit with a grinding wheel (30°, 45° or 90° towards the workpiece axis) or revolver with up to 3 grinding wheels

- Workpiece headstock with B axis

- Hydrostatic workpiece mandrel

- Centre zero feeler

- Fixed and/or powered dressing tools

- Tool change system

- Pre-process measurement (to recognise the position of a part and set it to the zero point)

- Measuring during the process (ø measuring and control operation during the grinding operation)

- Post-process measurement (to establish the ø, check the distances, set a new zero point, etc.)

- Coolant treatment

- Exhaust systems

- Engine cooling

- Remote maintenance

- and much more