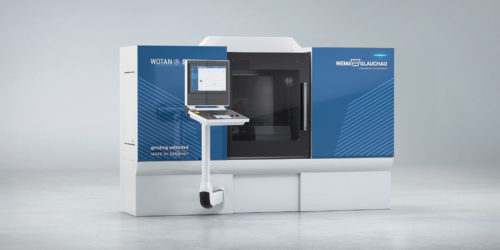

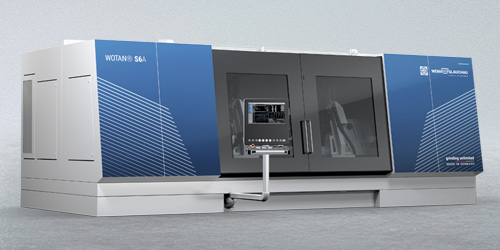

With our external cylindrical grinding machines, you can grind not only small, but also particularly large, long and heavy parts to the µm. A wide range of expansion options allows maximum precision in one clamping and perfect integration into automated production processes.

Service from one hand

Our machines are optimally customized for your grinding tasks and our financing options allow us to meet your business needs.

Key Facts

- Long parts of up to 5,000 kg with external lengths of Ø600mm and 5,000 mm

- Grinding wheels‑Ø 500, 600 and 750 mm

- Grinding wheels widths of up to 250 mm

Always on board is our innovative WOP-Touch™ user interface for intuitive operation directly on the machine or remotely.

#railway axles #rollers #pipes #shafts

175 mm

225/275 mm

350 mm

600 mm

1.000 / 1.600 mm

3.000 / 5.000 mm

100 kg

600 kg

1.500 / 5.000 kg

600 mm

1.000 / 1.600 mm

2.700 / 3.000 / 5.000 mm

Axis speed

0–20,000 mm/min

0–20,000 mm/min

0–15,000 mm/min

Round Tool Table

Direct drive/ Worm drive with 0,00005°

with up to 4 tool positions

Workpiece mandrel drive

Rolling bearing, belt drive without measuring system

Rolling bearing, direct drive with measuring system as C‑axis

Hydrostatic bearing, direct drive with measuring system as C‑axis

Rolling bearing, direct drive with measuring system as C‑axis

Options

- Pre-process measurement (to recognise part’s position and set zero point)

- In-process measurement (Ø measuring and regulating during the grinding process)

- Post-process (establishes Ø, checks distances, sets new zero point, etc.)

- up to hydrodynamic and hydrostatic guides

- Roller bearing and hydrostatically supported grinding mandrels

- Standing and rotating grinding dressers

- With and without a round machine table

- Internal grinding with internal grinding spindles possible

- Coolant treatment

- Engine cooling

- Suction systems

- Remote maintenance

- and much more